PW1000 TB-200 Thermal Break

Product Description

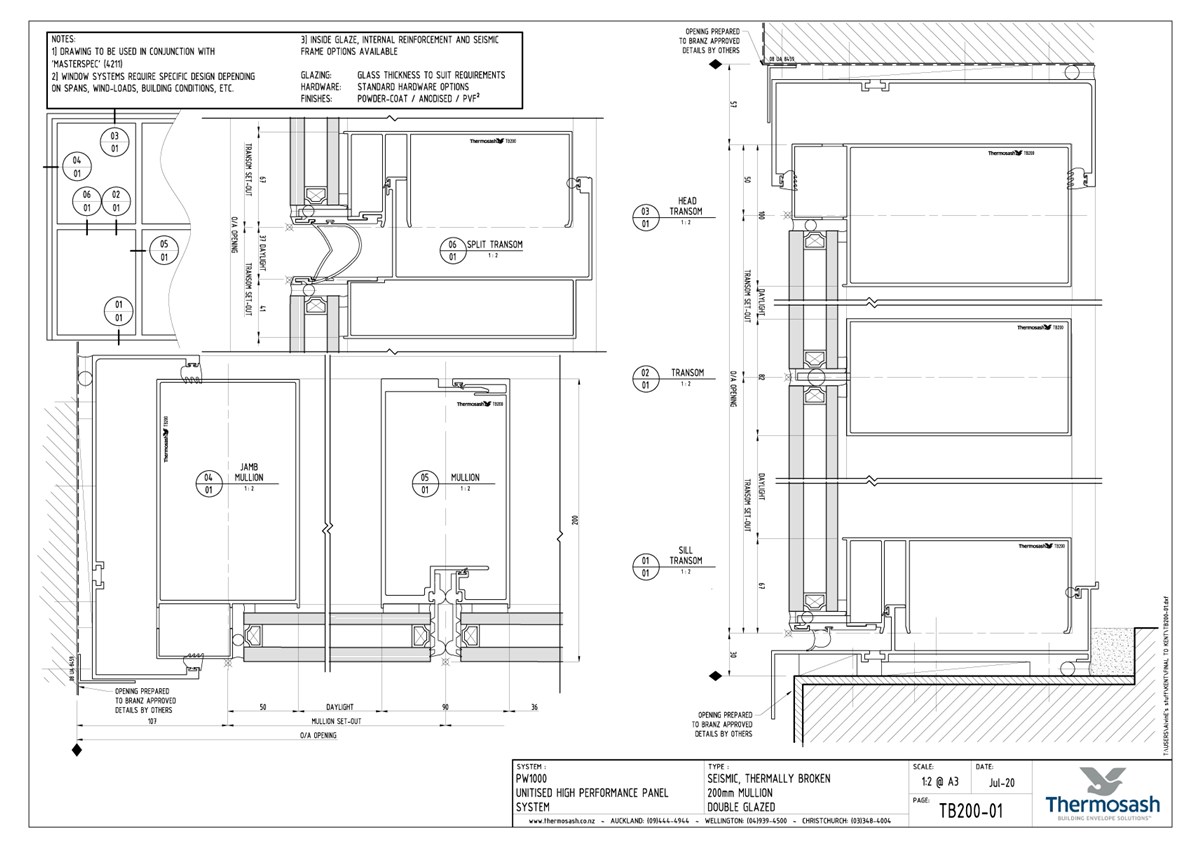

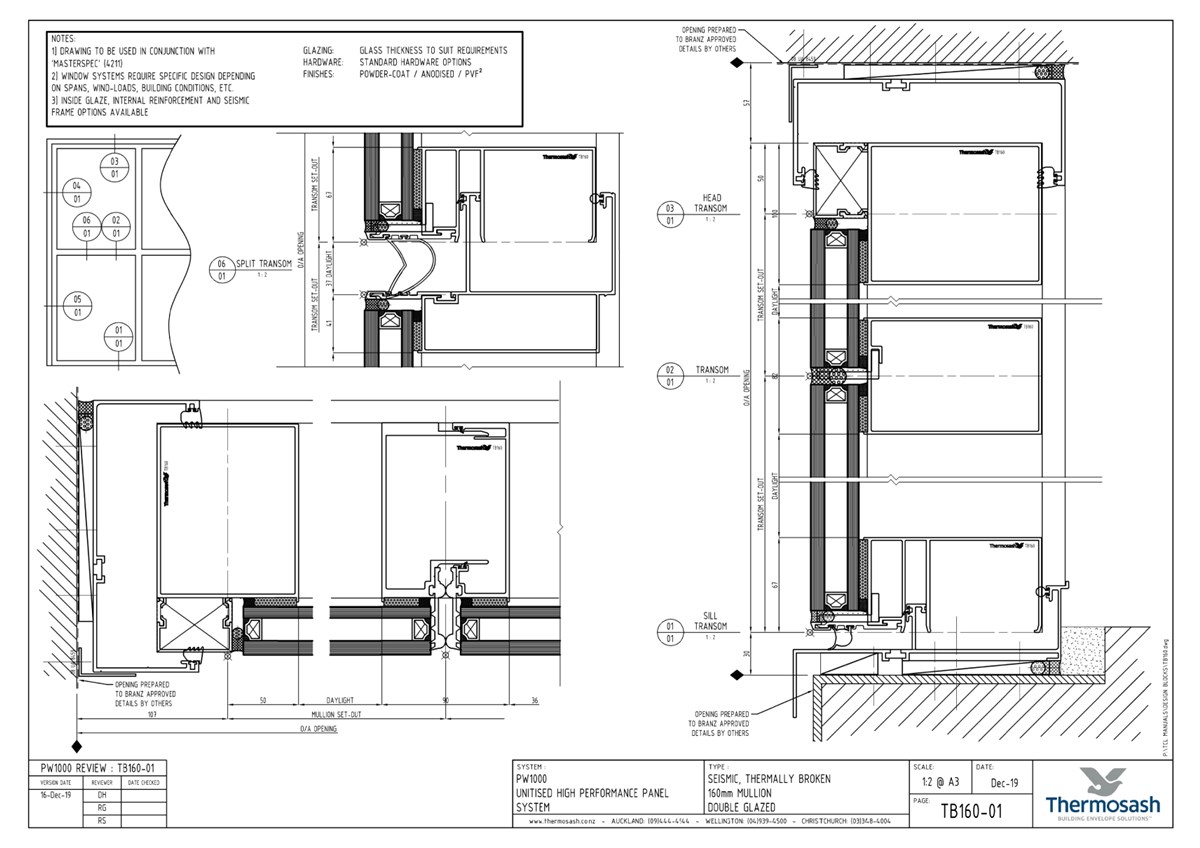

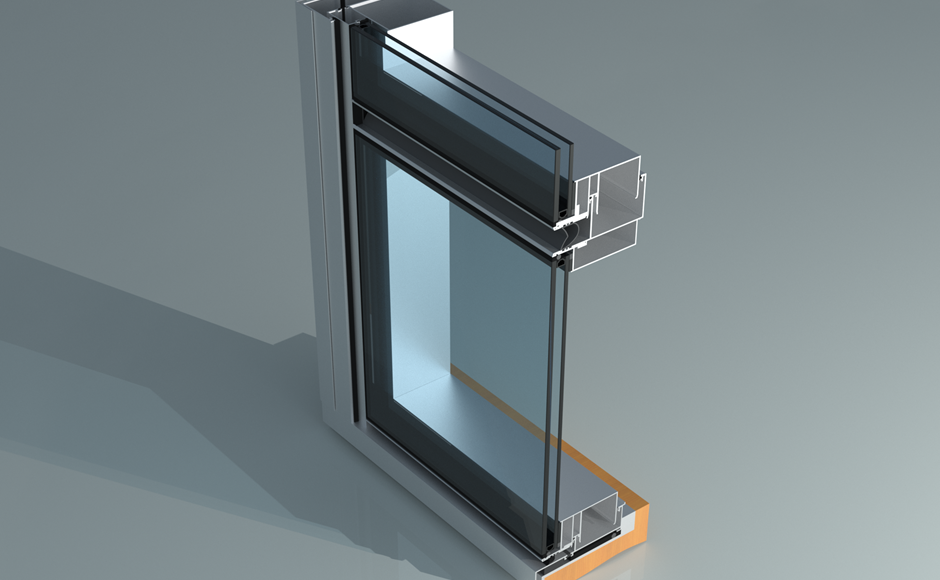

Thermosash PW1000TB-200 : Thermally broken four sided mechanically glazed engaged curtain wall - both horizontal transom, and vertical mullion elements are expressed.

A Thermal Break Suite is used when there is a need to reduce thermal transfer from inside to outside. Thermosash suites are often specified in areas of high condensation such as internal pool areas or where the temperature between inside and out can vary significantly.

Mullion Size: 200mm

Engineering

We custom design all our suites to suit our projects to maximise the efficiencies within the suite and often to incorporate added elements or unique building structures, building movements or floor heights.

Low-Carbon Aluminium

Thermosash partners with a local NZ-owned extruder achieving a lower carbon footprint than the global average - offering reduced upfront carbon emissions. (find out more about our Sustainable Aluminium).

Aluminium is 100% recyclable and all aluminium from refurbished sites and from our manufacturing process is environmentally managed back to our key suppliers and processed back into raw billet form.

Installation

Our systems are prefabricated and glazed in a factory environment, stored if necessary, and transported for just-in-time site delivery. We have highly skilled installation teams who work safely and effectively to close in buildings rapidly.

High performance facade solutions

Our team of designers and engineers are able to review your project and advise around the best solutions, taking into consideration environmental factors, sustainable outcomes, code compliance and budgetary requirements.