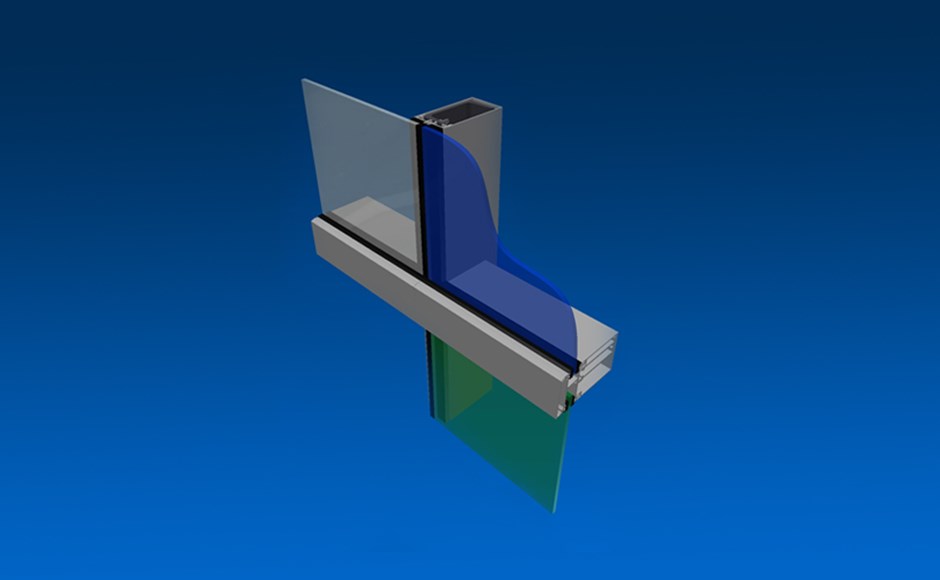

Section Sizes

- 100 / 150mm Mullions

- 100 / 150mm Transoms

Performance / Testing

Thermosash owns and operates the largest façade testing facility in New Zealand where we test our systems and custom designed suites to ensure compliance with the below codes or project specific requirements:

- AS/NZS1170 (Structural Design Actions)

- NZS4211 (Performance of Windows)

- NZS4223 (Glazing in Buildings)

- NZS/AS4284:2008 (Water / Air Pressure/ Air Leakage - Meets and exceeds minimum requirements)

All the Thermosash suites are independently laboratory tested to IANZ (International Accreditation New Zealand). Test certificates are available on request.

Maximum Spanning Ability

Thermosash specifically engineers the best suite option for your project taking into consideration span, structural system, and environmental loads (e.g. wind). The spanning ability will vary depending on the above.

Thermosash Suites are recognized as having the largest spanning systems on the market due to our specific engineering capability and the customised nature of the work we complete.

Warranty

The standard warranty is 10 years from the date of practical completion for these products. This covers workmanship and weather tightness, providing the subcontract includes fabrication, installation and glazing of all components, and the maintenance schedule is adhered to.

Maintenance

Maintaining glass, metals and stone are all particular to the environment that they are placed in: eg. marine, environmental pollution, exposure to natural washing, etc.

It is recommended by almost all material suppliers that building washing should occur every 3-6 months to prevent staining to glass and prevent environmental pollutants from corroding metals and to maintain the material warranties.

A full maintenance manual is provided on completion of a project for all the elements integrated within a project. Compliance to a maintenance schedule is essential to maintaining the quality of the installed product over time. Using Thermosash-approved facade maintenance contractor/personnel ensures the highest standards are met.