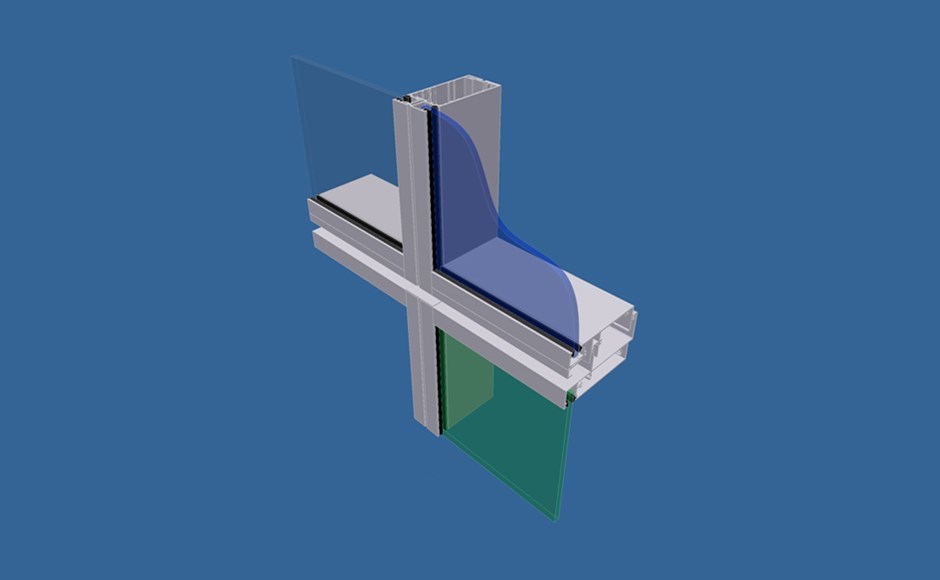

Pressure equalised design

The weathering design of these curtainwall suites follows recognised international curtainwall design principles - rainscreen pressure equalisation and system drainage - which requires primary and secondary weathering.

All internal cavities of the system are designed to be pressure equalised (i.e. no pressure differential between the outside face and any internal cavity). This feature allows the water which penetrates the rainscreen to drain and maintain ventilation. The rear air seal is critical to the system's weathering performance as air infiltration acts as the medium which transports water through to the building's interior, i.e. it is the prime cause of any leakage.

Non-vision rainscreen areas act as a primary water-stop, the second airseal and cavity acts as a backup to collect and drain away any water that manages to penetrate the primary rainscreen barrier, with an integral structural backpan.

Engineering

We custom design all our suites to suit our projects to maximise the efficiencies within the suite and often to incorporate added elements or unique building structures, building movements or floor heights.

Low-Carbon Aluminium

Thermosash partners with a local NZ-owned extruder achieving a lower carbon footprint than the global average - offering reduced upfront carbon emissions. (find out more about our Sustainable Aluminium).

Thermosash manufacture all of our own façade components in New Zealand, and primarily source materials were available from the New Zealand market to reduce transport distances and emissions from freight. We recycle 100% of all our metal waste.

Installation

Our systems are prefabricated and glazed in a factory environment, stored if necessary, and transported for just-in-time site delivery. We have highly skilled installation teams who work safely and effectively to close in buildings rapidly.

These prefabricated and glazed panels are delivered to the floors in crates and positioned by floor mounted cranes or monorail units. The panels have interlocking legs, requiring sequential placement around the building floor before the next level can be installed.

It is highly recommended that the units are installed from ground up in predetermined directional order to maintain the best detail connection between panels. Special methodologies need to be considered when recladding a building demands a top-down approach.

Curtainwall is almost always hung from the top of each floor section (dead loaded) and attached at the base of the unit to resist windload. The Thermosash specific engineered brackets attach at each floor either on the top of the slab, to the edge of the slab or under the slab as necessitated by the project design and engineering requirements of the selected system.

Performance / Testing

Thermosash owns and operates the largest façade testing facility in New Zealand where we test our systems and custom designed suites to ensure compliance with the below codes or project specific requirements:

- AS/NZS1170 (Structural Design Actions)

- NZS4223 (Glazing in Buildings)

- NZS/AS4284:2008 (Water / Air Pressure/ Air Leakage - Meets and exceeds minimum requirements)

All the Thermosash suites are independently laboratory tested to IANZ (International Accreditation New Zealand). Test certificates are available on request.

Warranty

The standard warranty is 10 years from the date of practical completion for these products. This covers workmanship and weather tightness, providing the subcontract includes fabrication, installation and glazing of all components, and the maintenance schedule is adhered to.

Maintenance

Maintaining glass, metals and stone are all particular to the environment that they are placed in: eg. marine, environmental pollution, exposure to natural washing, etc.

It is recommended by almost all material suppliers that building washing should occur every 3-6 months to prevent staining to glass and prevent environmental pollutants from corroding metals and to maintain the material warranties.

A full maintenance manual is provided on completion of a project for all the elements integrated within a project. Compliance to a maintenance schedule is essential to maintaining the quality of the installed product over time. Using Thermosash-approved facade maintenance contractor/personnel ensures the highest standards are met.