Sheet Metal Cladding Support - EN01

ENCLAD™ EN01 - Visible Fixed: suitable for thin smooth cladding.

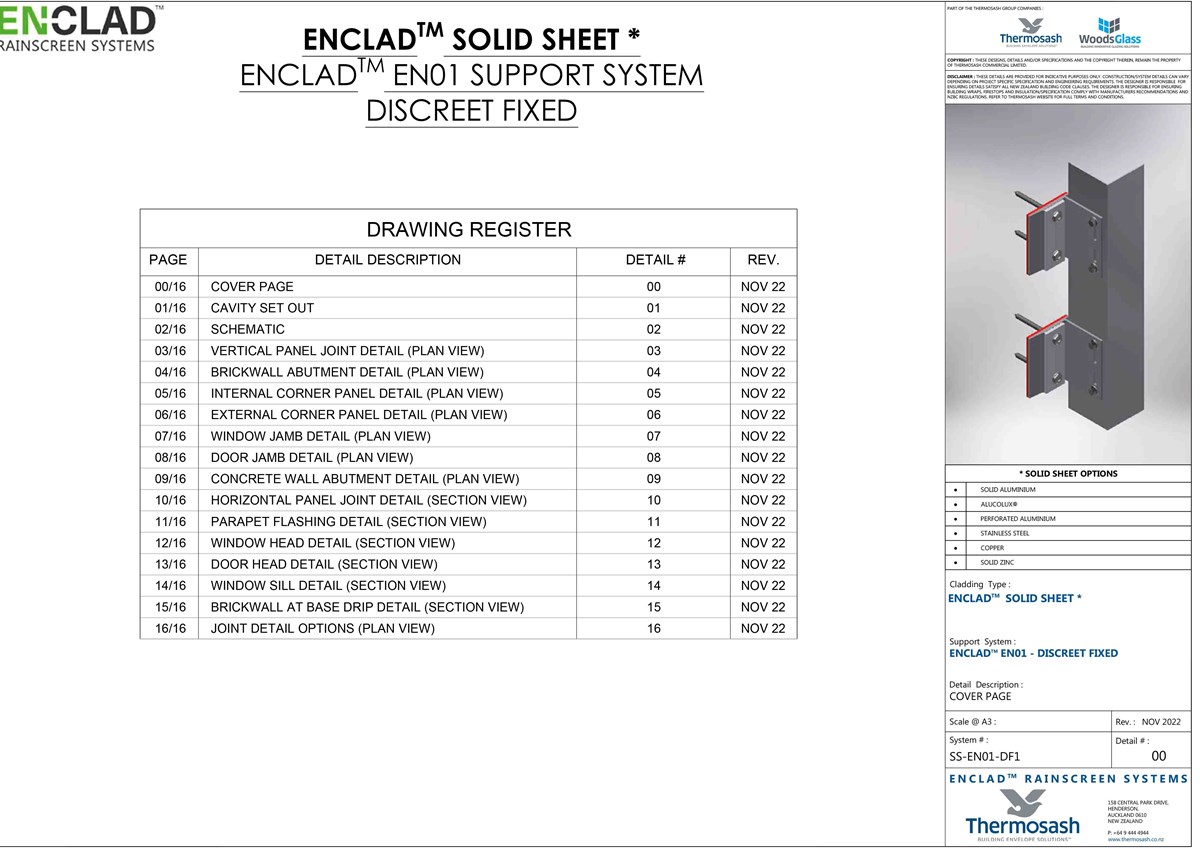

Download PDF showing window, door and wall abutment plan views, sections and details.

Solid sheet metals come in a range of materials and finishes that provide architectural design freedom and minimal maintenance requirements. Choice of material will be influenced by a number of factors including desired aesthetics, environment and climate, structural systems and budget.

These lightweight, durable and non-combustible panels can be folded into 3D shapes, curved, laser-cut, perforated or expanded into a mesh effects. Perforated metal sheets are generally used for feature elements or sun shading.

Available Solid Sheet Metals:

ENCLAD™ is Thermosash’s proprietary range of bracket profiles engineered specifically to support various types of rainscreen cladding. We have expert in-house teams working to ensure the design, engineering, procurement, fabrication and installation of our solutions deliver on custom specific project requirements and site-unique constraints.

Recommended ENCLAD™ support systems for Solid Sheet Metal rainscreen: