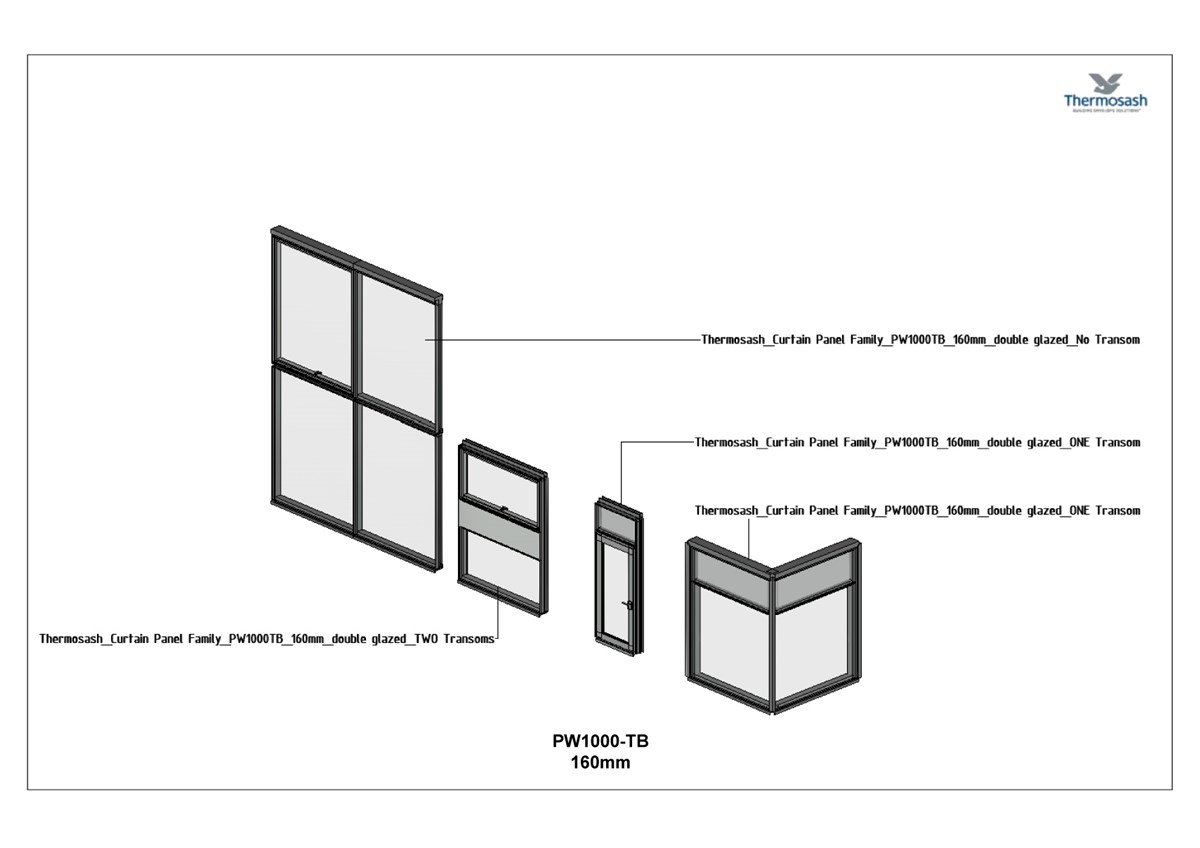

TB160 - PW1000 160mm Revit Family Showroom

Download Revit Family: No Transom, One Transom, Two Transoms for double glazed Curtainwall Panel

Thermosash PW1000-TB160 : Thermally broken four sided structurally glazed curtainwall suite designed for highrise or lowrise applications where the project has large spans or large panes of glass requiring higher strength systems.

Thermosash thermally broken unitised engineered aluminium systems offer exceptional thermal efficiency, as well as longevity in product life span minimising maintenance costs and maximising the return on invest on the facade of the building.

Mullion Size : 160mm

Integrated Elements

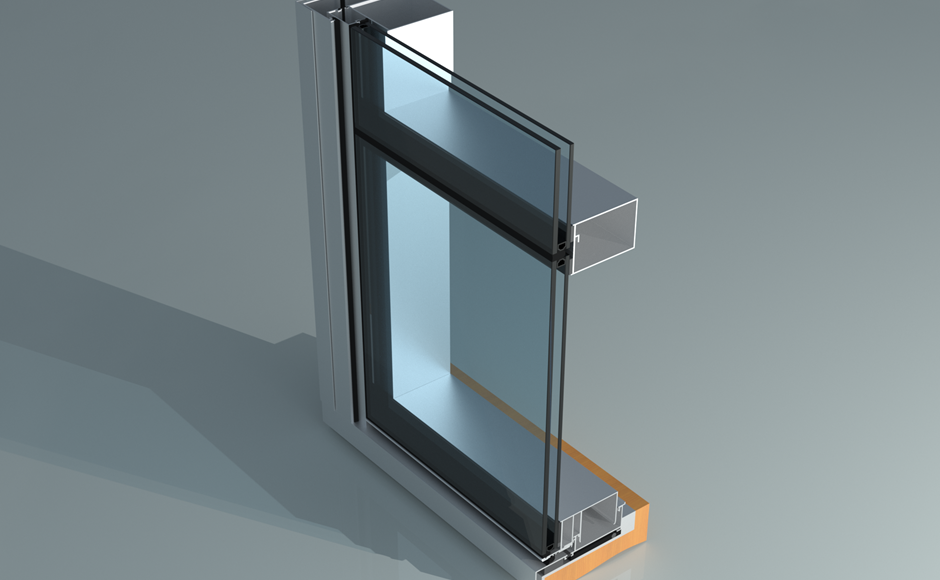

Thermal Break: Polyamide

The polyamide thermal break is integrated into the aluminium framing to minimise thermal bridging, which is the transfer of heat through conductive materials. Polyamide is a low-conductivity material that significantly reduces heat flow, improving the facade’s thermal performance and reducing energy consumption.

Low carbon aluminium - specify Thermosash DecarbalTM

Our Thermosash DecarbalTM aluminium achieves a very low carbon footprint that significantly outperforms readily available local & global alternatives - offering reduced upfront carbon emissions that positively contribute to sustainability project goals. For up-to-date carbon figures please contact us. Find out more about our Sustainable Aluminium.

Airtightness Performance

The Thermosash PW1000 TB facade system was independently tested to the AS/NZS 4284 standard for air infiltration. The system achieved an air leakage rate of less than 0.2 L/m²·s at a 150 Pa pressure differential (near zero), which is substantially better than the standard requirement of 1.6 L/m²·s set by AS/NZS 4284.

A lower air leakage rate means significantly less uncontrolled air movement through the building envelope. This reduces the loss of conditioned air, minimises drafts, and prevents the ingress of moisture-laden air leading to lower building energy consumption and reduced operational costs.

Thermal Performance

The calculated thermal performance of the curtainwall / panel wall suite is subject to many variables, from size of individual panels, glass performance, introduction of transoms and integrated solar shading (where bracketing may cause a cold link passage) and the spandrel depth (insulation).

Watertightness performance

Independently tested to AS/NZS 4284 standard for water penetration resistance. The system successfully withstood cyclic water test pressures of up to 2000Pa without any water penetration, significantly exceeding typical industry requirements.

The facade's ability to withstand extreme weather events provides long-term protection for the building's contents while reducing maintenance requirements and potential remediation costs associated with water damage.

Glass Performance

It is important to note that the aluminium section alone does not provide the thermal performance often expected. Glass specification is a significant contributor to the overall mechanical performance requirement of a building. The larger the glass pane the better performing the panel will be on average. Thermosash has access to suppliers of low carbon high performance glazing and can deliver an integrate solution.

Engineering Custom solutions

Thermosash design and detail the facade solution to meet project demand for seismic risk, wind loads, climate zones, corrosion zones and building importance levels as well as aesthetics, unique site constraints and budgetary requirements. We have extensive experience in integrating our systems and products to deliver a total facade solution.

Unitised pre-fabrication

Our systems are prefabricated and glazed at our manufacturing facilities (Auckland, Wellington and Christchurch) and can be transported for just-in-time site delivery. Due to prefabrication and the unitised modular design of our products and systems our highly skilled installation teams can close in buildings rapidly saving on programme time and mitigate follow on trade risk.

Facade Optimisation and Sustainability Reports

To achieve optimised high-performance outcomes, we offer our clients the option of a Project Sustainability Analysis that covers different aspects of the full sustainability cycle. When specifying our facade systems, clients can engage us to implement one or several of our Facade Optimisation Strategies to achieve their project sustainability goals. To gain the most from our strategies, talk to us early on in the design phase of your project.