Architectural Metal Pressing & Folding

Product Description

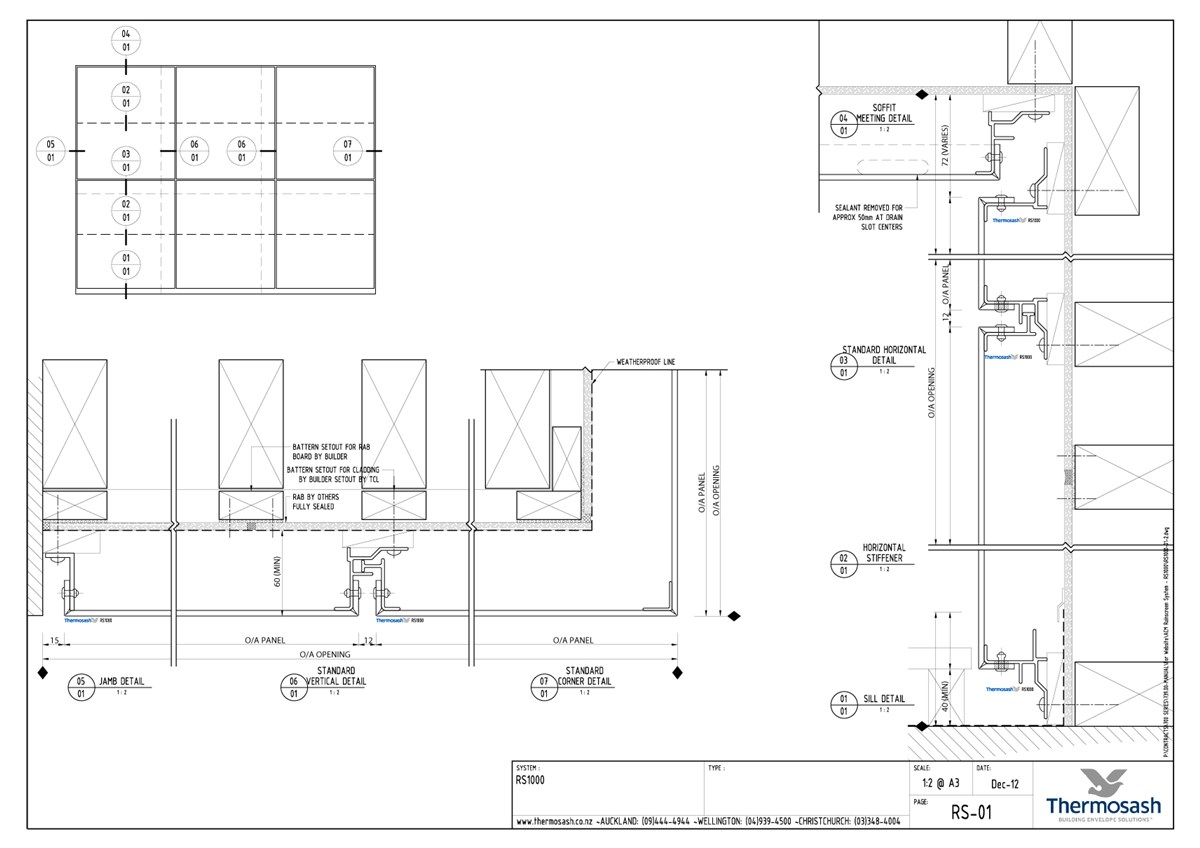

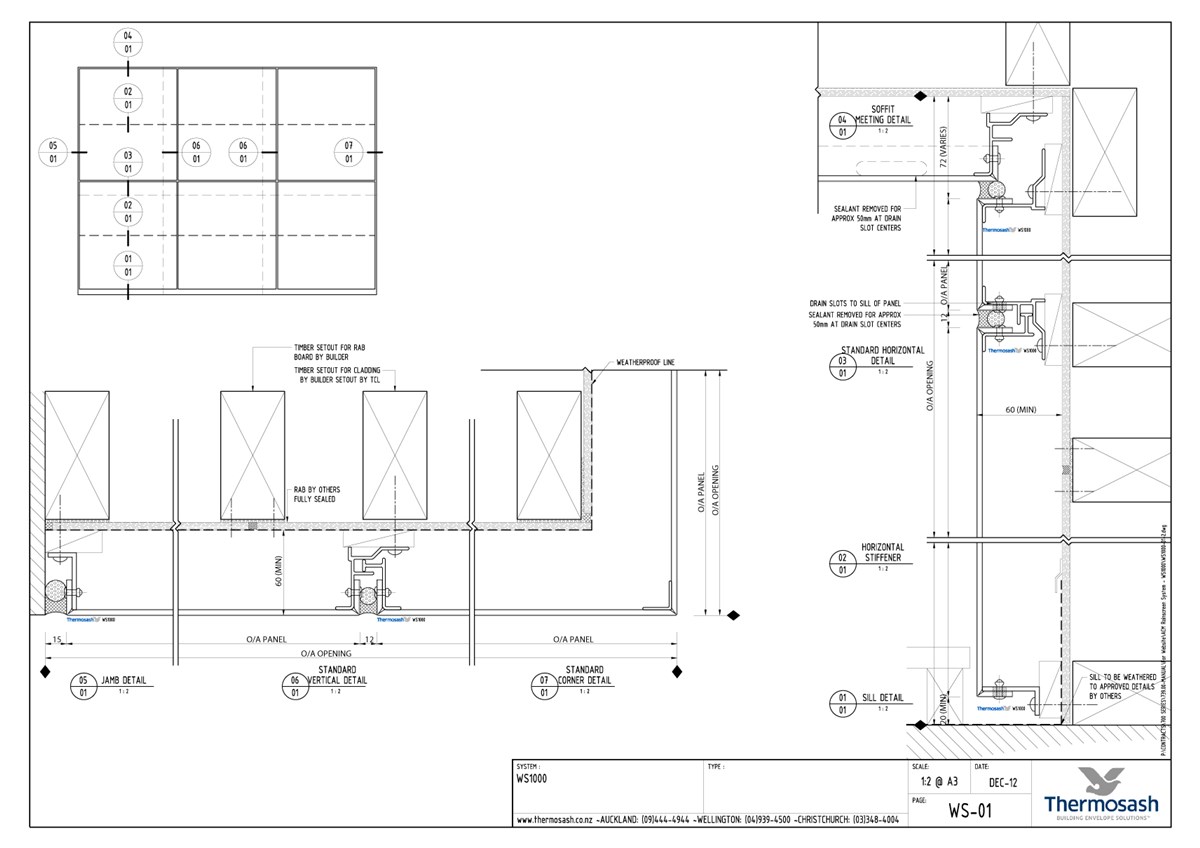

At Thermosash we manufacture literally thousands of architectural pressings a month. These may vary from a simple folded coping or aluminium flashing to a zinc or stainless steel architectural multi fold with pressing and reinforced welded corners and bracketry to act as an ancillary element to a curtainwall and replace what once may have been a much heavier and complex detailed precast concrete element.

We constantly reinvest in plant and machinery to enable us to undertake work that others cannot do - including CNC saws, wall saws, flat bed routers, water-bed cutters, CAM folding machines etc.

One trade solution

A significant advantage of incorporating Thermosash architectural pressings into your project is that they are integrated with the facade system - engineered and shop drawn to work together with the curtainwall not as a 'clip on' by a separate trade.

Thermosash Capability

There is little that Thermosash is not capable of in this building element - we see sheetmetal work as an important part of the solution that we provide our customers: to be able to provide a 'one stop shop' for building envelopes.

In order for Thermosash to confidently provide 10 year warranties on many of its building envelope solutions - we generally undertake the parapet flashings back to roof in order to integrate architecturally and ensure the end result is durable, not of dissimilar metals and consistent with our weather proofing detailing.